Remining Magnetite Tailings at Ernest Henry Mine

Overview of Project

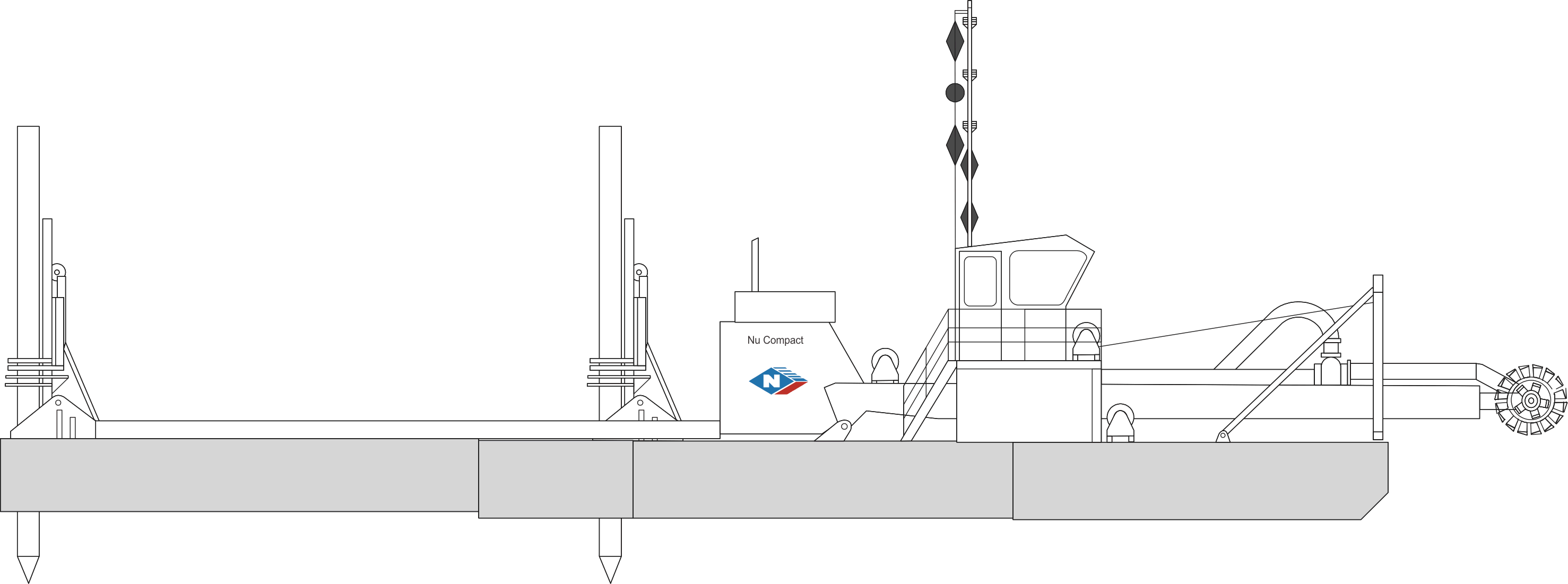

Ernest Henry Mining commissioned Neumann Dredging using our 300mm CSD Nu Compact to remine tailings from the Tailings Storage Facility to recover magnetite. Nu Compact pumped the reclaimed tailings via a 1000 metre long HDPE pipeline directly into a processing circuit in which the magnetite was concentrated.

Scope of Works

Supply and operate dredging equipment on a 24/7 basis. Dredge and pump a consistent feed density to the processing plant.

Innovations

The dredge is fitted with an RTK navigation system to follow the mining plan accurately. Flow and density meters are fitted to the slurry line to help ensure a steady tonnage is pumped into the magnetite circuit. In addition, slurry density was controlled via dilution water into the suction pipe, automated via a PLC against the dredge’s density meter.

Nu Compact CSD was used for this Project

The Nu Compact cutter suction dredge has been involved in the following projects:

- Lake Illawarra Channel Entrance Dredging,

- Tallebudgera & Currumbin Creeks Dredging,

- Canaipa Passage Maintenance Dredging.