Caval Ridge Mine Dredging

Overview of Project

BMA contracted Neumann Dredging to remove 475,00m3 of mud from the floor of an open cut coal mine as part of the preparation for reopening the pit.

Silt and sediment have accumulated on the pit floor. The task was to dredge this mud and pump it out of the pit for placement in an adjacent excavation.

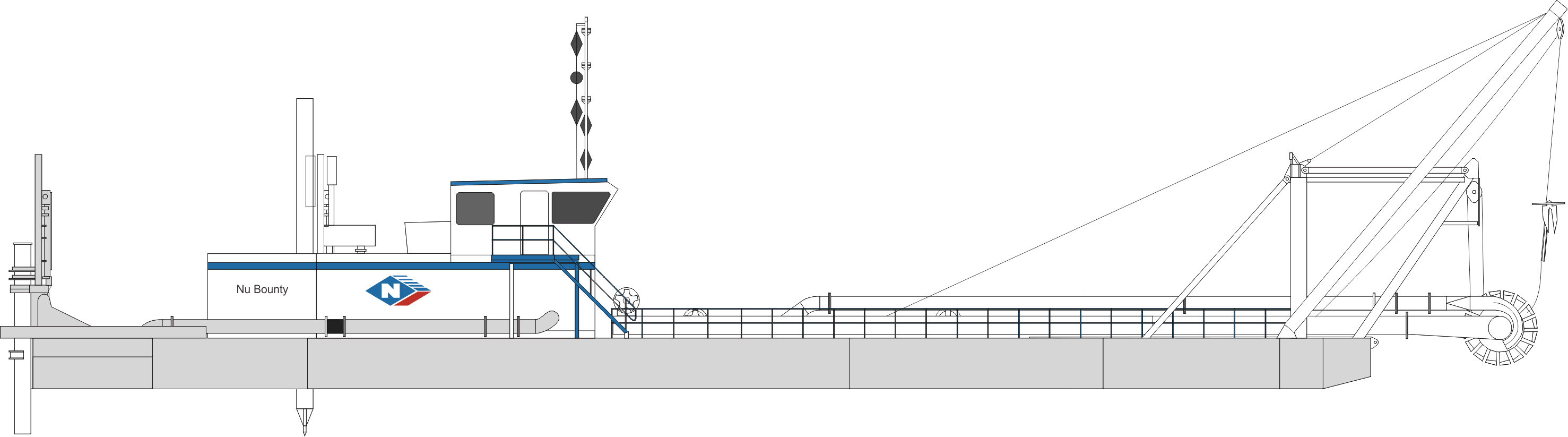

The 450mm bucketwheel cutter suction dredge Nu Bounty was mobilised for this project along with a booster station and 2500m of pipeline. We transferred water back from the discharge area using a return water pump and pipeline to enable an orderly drawdown of the water level in the dredge pond.

All equipment was diesel-powered.

Innovations

- Management of pumping through a 40m vertical pipe section to the booster pump located on the cast bench,

- Trialling of a discharge restriction valve to manage pressure at the discharge line highpoint while maximising the siphoning effect.

Challenges

- The draw-down of the water levels had to be carefully managed to maintain the pit’s geotechnical slope stability.

- Strict design cut conformance was managed and reviewed using onboard RTK navigations systems,

- Dredging was carried out on a 24/7 basis to expedite the works.